Written by Shambhavi and Utkarsha

According to a study by Netherlands consulting firm Kearny, green products are 75-85 per cent more expensive than conventional products. When it comes to upcycling, the common assumption is that upcycled products are inherently cost-effective since the raw material is pre-existing.

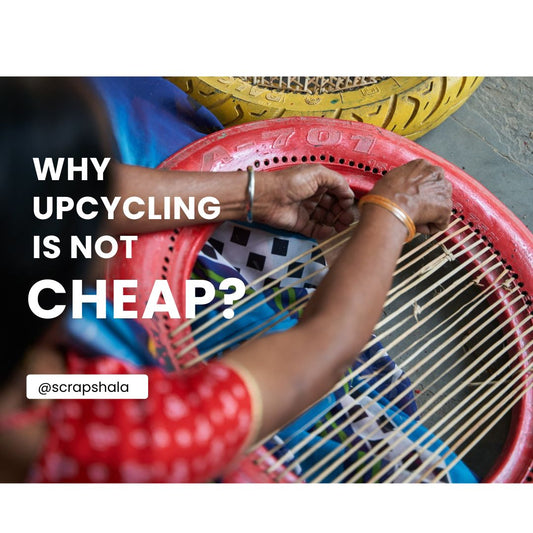

Let’s first understand what upcycling is and how it’s different from recycling.

Up-cycling, as the name suggests, is a process of repurposing pre-existing discarded materials or materials no longer of use to create a product of higher value, quality and function. This helps reduce the pressure from landfills and is often considered a better alternative to recycling where the quality of the material may get affected during the process.

Now, many of us assume that if the raw-materials are already there, why are upcycled products more costly than their non-upcycled counterparts?

If you have ever wondered about this, keep reading!

Factors Contributing to the Expense of Upcycled Items

While the raw materials already exist, let’s understand the entire process of up-cycling and what brings up the price of such products?

Sourcing Raw Materials

Rarity of Suitable Materials and Limited Supply

There is no control over the quantity and quality of raw materials when it comes to upcycling. Materials that are suitable for upcycling are non-uniform in quality and can’t always be sourced in bulk. This rarity of suitable materials & limited supply makes it a challenge to make identical products in bulk, thereby adding to the final cost.

Material Collection and Transportation Costs

Unlike non-upcycled products, where new raw materials are sourced from a single location in desired dimensions, the discarded materials come from diverse locations and vary in all kinds of sizes and conditions. This unavailability of desired scrap materials in bulk, the logistics involved in sourcing forsaken materials from several different locations, and the warehouse cost involved with it collectively adds up to the cost and makes the product expensive.

Misconception of "Free" Materials

The notion of ‘discarded materials are always free’ can be misleading. Not all discarded materials are free. Tyre tubes for that matter come at a cost, so does discarded glass. Discarded tyre tubes of a car or a SUV costs anywhere around Rs.300 - Rs.400, which is at par with the cost of factory made fresh raw materials such as leather or other alternatives.

Those raw materials that are in fact free, demand significant investments in time, efforts, and creativity. The supposedly ‘free’ materials require searching, planning, skilled craftsmanship and more.

Sorting and Cleaning: Prioritizing Hygiene

In conventional manufacturing, raw materials that are used are brand new. In the upcycling sector, the materials are pre-existing. This creates a necessity to painstakingly sort and clean the material before the production begins. The additional step of cleaning and sorting is a fairly time-consuming process, contributing to the overall cost of the upcycled product.

Design and Production

Unique Designs

The entire design-to-manufacturing process gets reversed in the context of upcycling. Usually a product is first designed, then the raw materials are finalized and sourced, and then the end product is manufactured. However, in the case of upcycling, the material comes first, and then based on the availability and impact of dealing with a certain type of scrap material, the design is tailored and then the product is crafted. This doesn’t stop artisans from creating gorgeous products. This uniqueness, however, isn't happenstance; it's the result of years of experience, understanding of materials, design sensibilities, creative vision and skilled craftsmanship.

The Human Element vs. Mass-produced Items

In contrast with mass-produced items rolling off in assembly lines at breakneck speed, upcycled products demand a slower, more conscious pace. Upcycled offerings, a testament to being individualistic, handmade, and artistic, affirm the theory of quality over quantity.

In addition, it is crucial to acknowledge the lack of awareness and the stigma associated with working with scrap materials. There exists a noticeable resistance among artisans towards utilizing pre-used materials and experimenting with tools on these unconventional resources. This reluctance affects the exploration in craftsmanship. It hence requires educating not just the buyers but the makers as well!

Upcycling, in India, is mostly done in small-scale workshops like Scrapshala, as the local demand for these products is not very high. The artisans invest time in learning about the materials to breathe life into discarded materials. The time-consuming nature of the transformation process is a deliberate choice to ensure quality. This value addition becomes the most vital element that sets each of these offerings apart from one another and hence becomes more valuable than the ones produced in mass.

Quality control challenges

Quality control challenges in the field of upcycling contribute to increased costs in the production process. Due to the variations in the discarded material composition and condition, and the unpredictable nature of such materials in terms of wear, color, and structural integrity, ensuring consistent quality across products, becomes challenging.

The absence of standardized testing methods for upcycled products requires each brand to customize their own quality control processes. This increases both time and resources used, thereby adding to the operational expenses.

Limited 'Economies of Scale' in Upcycling

The principle of Economies of Scale that says “the more you produce, the less it costs”, faces challenges in the world of upcycling. Each raw material sourced for upcycling is unique in terms of sizes, quality, material, finishing, etc.

Mass production is only feasible in certain categories of raw materials that are available in abundance. This is only possible when a robust ecosystem is in place for product development, coupled with a sizable market of buyers that encourages increased production. The sourcing to designing process then becomes a more organized and streamlined task. Hence, when it comes to upcycled products that are in limited demand, brands like Scrapshala cannot rely on economies of scale. This necessitates to charge more for the product.

Market Trends and Consumer Demand

According to a study by Business Wire, a shift in the purchasing behavior of 85% of the global population has been recorded. The shift is towards being more sustainable as observed over the past five years. Whereas, Harvard Business Review suggests that 70% of global consumers state that having a sustainable life is important to them. Reports like such indicate a significant switch towards a more nature-inspired and sustainable way of living which is contributing to the growth of the green industry.

With sustainable products replacing factory-made nature-identical products in developed countries like the United States, United Kingdom, etc, the increase in demand for these items is pretty apparent at this point. This directs toward the shifting preferences and willingness of consumers to purchase premium-priced sustainable products to lead a life that’s eco-conscious even in developing countries.

While the initial investment in upcycled items may be higher, it reflects Scrapshala’s commitment to environmental responsibility and supports a more equitable production chain. Understanding the intricacies behind the pricing dynamics of upcycled products enhances consumer awareness and encourages a conscious approach to sustainable living.

Check out Srapshala’s comprehensive range of upcycled products, here.